Cleanroom Film

Moisture-Barrier Film for Vapor Protection and Oxygen Transmission

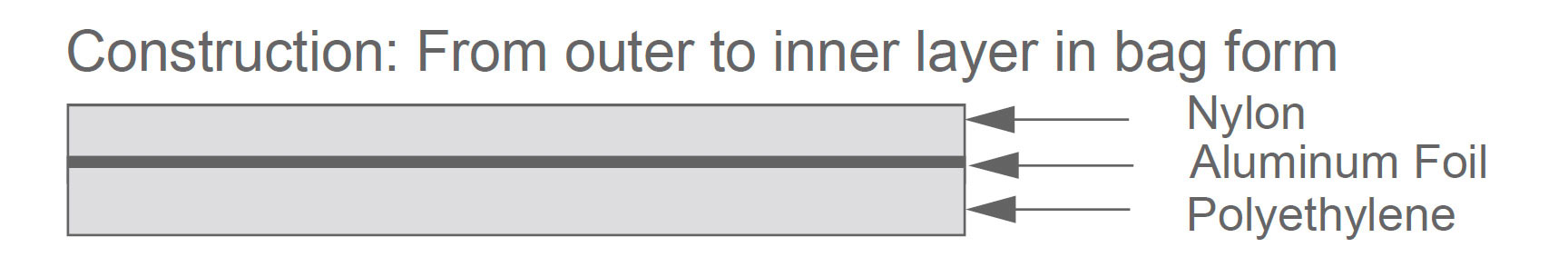

Moisture-barrier film is used for cleanroom products that require the utmost protection from moisture vapor (MVTR) and oxygen transmission (OTR). Film composition is Nylon/Foil/Polyethylene. It is a strong, opaque film with a distinctive foil appearance. It does not have any static dissipative coating which minimizes outgassing and non-volatile residue. Pristine Clean Bags® moisture-barrier film is manufactured in an ISO-certified cleanroom and certified clean to IEST-STD 1246D.

Cleanroom Film Specifications

| Property | Nominal Value | Test Method |

| Total Thickness | 6.0mil +/- 10% | ASTM D-374 |

| Color | Silver | N/A |

| Punture Resistance | >/= 19lbs | FTMS 101C, Method 2065.1 |

| Tensile Strength | MD Yield 4000 psi TD Yield 4300 psi |

ASTM D882 |

| Heat Seal Strength | >/= 16lbs/inch | ASTM D882 |

| MVTR (100F, 100in 2/24hrs) | < 0.0006 grams | ASTM F-1249 |

| OTR (20° /100in 2/day) | 0.003grams | ASTM D 3985-05 |

Heat Seal Conditions: 250°F-375°F,0.5-3.5sec, 30-70PSI

- 21 CFR177.1520(c), paragraph 2.2 compliant

- European Commission (EU) No 10/2011 compliant as of 4/9/2012.

- Components of animal origin have not been knowingly added to this product.

- This product is not manufactured with any of the Substances on Very High Concern (SVHC).

- Complies with the requirements of Article 4.1 of EU Directive 2011/65/EU (RoHS)

- This product is not intentionally manufactured with Bisphenol A, natural rubber, natural latex

Phthalates, Fluorotelomers, Perfluorooctanoic acid (PFOA) or Perfluorooctane sulfonate (PFO - Complies with California Proposition 65

Notice: All statements, information and data given herein are believed to be reliable, but are presented without guarantee, warranty or responsibility of any kind, expressed or implied. The values presented in this data sheet are typical and are not to be interpreted as product specifications.

Looking for Custom Clean Room Film? Contact Us Today