4 Essential Things to Know About Cleanroom Bags

If you run a company in the industry that produces medical equipment, optical devices, electronics, vehicle sensitive parts like sensors, and similar products that must be produced in a highly controlled environment, you need cleanroom bags. The primary purpose of cleanroom bags is to store and transport items (surgical gloves, caps, dental tools, sensitive medical and biopharma equipment, sound cards, computer components, etc.) safely in and out of cleanrooms without the risk of potential contamination.

You must be aware of the importance of clean room packaging quality, as it may directly impact your success or failure. That said, you need a reliable, cleanroom bag supplier that maintains the highest level of traceability and conformance to meet your cleanroom packaging specifications.

Both medical equipment and computer components require clean room packaging with low bioburden levels and the ability to restrict airborne particles. The reason is simple – airborne particles and microorganisms may significantly affect them if not adequately protected.

Cleanroom bags come in different shapes and materials, and each of them is intended for a different purpose. If you are unsure which one is the right for you, let us lead you through the 4 critical factors worth considering before opting for a particular item.

What is a Cleanroom?

A cleanroom is an environment free of pollutants like dust, aerosol particles, and airborne microbes. Cleanrooms tend to provide the cleanest possible area for manufacturing electronics, medical equipment, and pharmaceutical products.

Cleanrooms are often classified into different contamination levels depending on the exact amount of contaminants allowed in the area per cubic meter. Other variables controlled by cleanrooms include temperature, humidity, and airflow.

Industries that regularly use the cleanroom, thus cleanroom bags, are the following:

- Military and aerospace industry

- Research facilities

- Pharmaceutical companies

- Medical laboratories

- Computer component production

- Optics and lens manufacturing

- Nanotechnology applications

- And similar.

What is the Main Difference Between Sterile and Clean Rooms?

Although they share some characteristics, sterile rooms and clean rooms are not the same. While clean rooms are highly controlled environments where the air is filtered from contaminants and airborne particles, using HEPA filters or similar fan filter units, sterile rooms go a step further. Namely, sterile environments are 100% free of bacteria and microorganisms and are required for specific tasks, including injections, vaccines, organ transplant solutions, infusions, etc.

What to Look for in Cleanroom Bags?

In order to choose suitable cleanroom bags for your medical, computer, aerospace facility or pharmaceutical equipment, you need to look for specific cleanroom bag features.

1. Cleanroom Bag Types and Formats

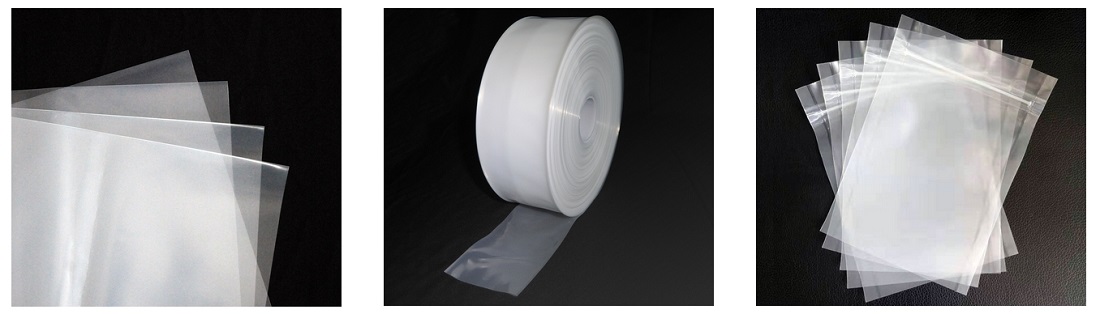

There is a wide variety of cleanroom bag types you can choose from based on your specific needs and industry requirements. The most common categories include the following:

LDPE Poly Bags

LDPE poly bags (low-density polyethylene) feature the most versatile materials intended for general purpose cleanroom applications. They are characterized by good strength, moisture barrier, and clarity. Clear polyethylene cleanroom bags are made from barefoot resin and are translucent. However, the formulation can be modified to improve clarity.

These cleanroom bags are suitable for various applications, especially markets, which choose them for clarity, flexibility, and supple feel. Additionally, LDPE bags are a go-to choice for storing electronics, pharmaceuticals, medical tools, biotech applications, or gamma-irradiated products.

However, LDPE poly bags are not an ideal choice for freezer applications due to their poor low-temperature capabilities. You should also avoid them for microwave or steam sterilization as they start to soften at 170-180 degrees Fahrenheit.

LDPE Easy Tear Cleanroom Bags

The most prominent advantage of the LDPE easy tear cleanroom bags is an easy tear formulation that allows you to open the bag with gloved hands. That way, you can avoid potential damage caused by knives, blades, and other sharp tools you normally use to open the bag.

LDPE easy tear bags are available in various thicknesses, and you can choose between those with or without re-closeable zippers. These are suitable for different purposes, from packing computer components to gamma-irradiated products, and manufacturers tend to choose them for their practical design.

Remember not to use LDPE cleanroom ziplock bags in microwaves or freezers since they cannot withstand extreme temperatures.

HDPE Bags

HDPE plastic bags (high-density polyethylene) are the perfect choice whenever you need a cleanroom bag that features excellent puncture and temperature resistance, moisture barriers, and strength. HDPE bags are a necessity in industrial usage, mainly due to their strength and density ratio. Thanks to its higher density, the moisture transmission in or out of the bag is quite limited.

Unlike LDPE bags, which are not as temperature-resistant, HDPE bags are durable in a wide temperature range. Namely, their embrittlement temperature is -180°, while the softening point goes up to 210-220°F.

LDPE vs. HDPE Bags

The main difference between LDPE and HDPE bags lies in their materials. While LDPE has less tensile strength than HDPE, it features greater ductility. On the other hand, HDPE is denser and has higher resilience than LDPE.

Both can be used in manufacturing, pipe protection, automotive industry, industrial applications, etc.

Nylon Cleanroom Bags

Nylon cleanroom bags are transparent, puncture- and scuff-resistant, incredibly strong, and capable of resisting elevated temperatures. In addition, the film provides an exceptional barrier to oxygen and moisture transmission. Therefore, a nylon cleanroom bag is commonly used to reduce tears and scuffing caused by friction rubbing.

The material performs very well in vacuum applications and can remain stable even during and after gamma radiation. If you choose bags with an easy tear feature, you and your technicians will easily open the bag even with gloves, preventing damages and injuries caused by blades, knives, or scissors.

Moisture-Barrier Cleanroom Films

Consider moisture-barrier cleanroom films whenever your products require the utmost protection from moisture vapor and oxygen transmission. These films are strong and opaque, featuring a distinctive foil appearance.

It allows you to package sensitive electronics or medical devices, preventing contamination, airborne particles, and microorganisms from potentially damaging your items.

Cleanroom Poly Tubing

Cleanroom poly tubing can be used for various applications, such as medical and automotive purposes. It is made from 100% virgin low-density polyethylene and is often sold in large rolls similar to oversized Scotch tape. It opens at its mouth, allowing you to put objects lengthwise into the tube and have it heat sealed, stapled, or taped in place.

Poly tubing is exceptionally durable, strong, and excellent for protecting your items from contaminants and compromising particles.

2. Cleanroom Bag Materials

Cleanroom bags are available in different materials. Due to their specific features, they are suitable for various purposes, depending on what you need them for.

Anti-Static Nylon

Anti-static nylon is an excellent choice for products requiring toughness, cleanliness, and maximum abrasion resistance.

Polypropylene

Polypropylene is considered one of the safest types of plastics used on the market today. It is commonly used to store foods, such as yogurt and cream cheese, and its high heat tolerance allows you to heat it in a microwave. Besides, polypropylene cleanroom bags can be used for packing toys, plush animals, or sharp tools.

Aclar

Aclar refers to a high-density fluorocarbon film with potent water vapor barrier properties. Aclar cleanroom bags are suitable for aerospace and military applications, as well as protecting pharmaceutical, medical, and electronic equipment.

Teflon

Teflon cleanroom bags ensure high quality and the utmost cleanliness. They can withstand high-temperature applications and extreme weather conditions.

Desiccant Bags

Cleanroom desiccant bags are filled with a specific material that absorbs moisture, protecting the items from getting wet. They are commonly used for packing medicines, food products, or leather.

3. Cleanroom Bag Classes

Another essential factor worth considering refers to the cleanroom class. The cleanroom class relates to the levels of cleanliness inside the cleanroom, which is based on the quantity and size of the particles per cubic meters of air.

The US and Canada follow the ISO 14644-1 classification system, which classifies the rooms from the “cleanest” to the “dirtiest.” Note that although space is ranked as the “dirtiest,” it is still cleaner than a standard room.

Let’s take a closer look at the most common ISO cleanroom standards:

- Class 100 (ISO 5)

- Class 1,000 (ISO 6)

- Class 10,000 (ISO 7)

- Class 100,000 (ISO 8)

4. Trustworthy Cleanroom Bag Supplier

Choosing a reliable cleanroom bag company is quintessential to ensure you’re getting what you’re looking for. You need to be sure that an outsourcing company follows the standards and guidelines when manufacturing cleanroom bags to avoid potential inconveniences and hazards resulting from the lack of cleanliness.

Let’s go through the questions you can ask a company before opting for their products:

What Packaging Solutions Do You Offer?

It is essential to have an insight into the solutions the company offers. Still, don’t hesitate to go beyond the questions regarding their inventory, but ask about materials they use for their cleanroom bags, the sizes available, customization capabilities, etc.

What Do You Think About the Quality of Your Work?

You can expect the company to say that their products are of superior quality and up to industry standards. But that doesn’t guarantee anything. Insist on learning more about the standards they follow and whether their products have been inspected.

Do You Have Return Policy?

Since the collaboration with the cleanroom bag company is a substantial investment, you’ll want to know what happens if things go south. Ask about their money-back guarantee to check whether you’re getting a refund upon receiving faulty cleanroom bags.

Pristine Clean Bags® – Top Trusted Cleanroom Bags Supplier in the US

Pristine Cleanroom Bags by Jarrett Industries are manufactured according to the highest quality standards in the environmental control packaging industry. Apart from offering a wide variety of products for different businesses, we ensure all our bags and films maintain high levels of cleanliness that allow you to store your electronic, medical, or automotive equipment with peace of mind. The materials we use are EU and FDA-approved.

We provide the following cleanroom materials: barrier bags, high and low-density polyethylene, nylon, tear notches, easy-open, zip lock, printed, sheeting, anti-static, FEP. Jarrett Industries also has custom cleanroom resin blends. Our clean room packaging items are supported by an ISO-certified quality system and continuous environmental monitoring.

Our global supply chain enables us to support our customer’s facilities within the US as well as warehousing overseas. Plus, our unique strategic sourcing ability allows us to offer pricing on cleanroom bags that are 20-30% below the US and EU markets.

At Pristine Clean Bags®, we are dedicated to never-ending improvement, ensuring our products meet our clients’ needs and expectations. Don’t hesitate to call us at (410) 581-0303 – our experts will be happy to answer any questions you might have.