Automotive Clean Room Supplier : Tubing and Cleanroom Bags for Automotive and Electronic Components

Pristine Clean Bags®: Top-Trusted Automotive Manufacturing Cleanroom Bags

Cleanroom bags are used in an array of applications requiring strict contamination control, including the automotive industry and electronic component use. Cleanroom packaging is essential for keeping the products safe from contaminants and airborne particles that could affect their quality. Pristine Clean Bags® offers peace of mind with automotive clean room bags made of FDA- and EU-compliant materials free from animal sources or harmful substances.

Pristine Clean Bags® is a part of Jarrett Industries, a company with 42 years of experience in the field. We are proud to be a leading cleanroom packaging supplier for companies in different industries, from life science and aerospace to automotive and electronic component production.

We provide different cleanroom packaging supplies for automotive assembly and manufacturing. You can choose between cleanroom bags, tubing, and cleanroom polyethylene film, depending on your unique needs. Our products are manufactured in an ISO-certified environment and do not contain traces of animal sources or Substances on Very High Concern (SVHC).

Top 6 Reasons to Choose Our Automotive Clean Room Packaging

42 Years of Professional Experience

European and US Supply Chain

30% Off US and EU

ISO-Class 5 Automotive Cleanroom Bags

FDA-Compliant Cleanroom Products

Custom-Tailored Automotive Clean Room Bags

#1 Automotive Manufacturing Cleanroom Packaging Supplies: Bags, Films, and Tubing

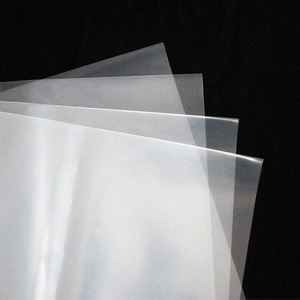

We offer a broad range of automotive cleanroom packaging supplies suitable for highly controlled and ISO-certified spaces. Our bags, films, and tubing are made of virgin resins, non-animal, and anti-static sources that mitigate the risk of contamination and meet FDA and EU standards.

If you have any technical questions regarding our automotive cleanroom packaging supplies, don’t hesitate to reach out to our customer support or submit the contact form.

ESD Bags

ESD bags (static shield bags) are perfect for protecting your sensitive electronic devices and semiconductors. If your industry requires safe transport and storage for outside of the safe working area (EPA) look no further than Pristine ESD bags. Protect electronic products like SSD hard drives, motherboards and memory with our ESD shielding bags. Click this link and learn all the technical details about ESD bags.

LDPE Bags

LDPE bags, also known as low-density polyethylene poly bags, are excellent for storing automotive and electronic components. They are characterized by incredible strength, clarity, and moisture barrier. Our LDPE bags are manufactured in a highly controlled, ISO-certified environment, ensuring the utmost quality and protection. Order LDPE bags online.

HDPE Bags

HDPE, or high-density polyethylene bags, are extremely puncture- and temperature-resistant, have tensile strength, and great moisture barrier. HDPE bags are convenient for storing heavy automotive parts and can withstand extreme temperatures. Get more information about HDPE bags.

Nylon/PE Cleanroom Bags

Nylon/PE cleanroom bags feature excellent puncture and scuff resistance, transparency, and robust design. The Easy Tear formulation lowers the risk of product damage due to knives or sharp blades, allowing technicians to open the bag with gloved hands. Nylon/PE bags are produced in an ISO-certified environment and are suitable for the automotive industry. Learn more about Nylon/PE bags.

Cleanroom Poly Tubing

Cleanroom Poly Tubing is suitable for storing automotive or electronic components longer in length or when you need to pack the same item continuously. Learn more about cleanroom poly tubing.

LDPE Easy Tear Bags

LDPE bags with Easy Tear formulation take your experience to the next level. Tear notches allow you to open the bag with gloved hands quickly and without scissors or sharp blades. That way, you prevent potential product damage. Order LDPE Easy Tear bags with or without re-closeable zippers.

Moisture-Barrier Film

Moisture-barrier film is incredibly suitable for automotive parts that require the utmost protection from factors like oxygen transmission (OTR) and moisture vapor (MVTR). Moisture-barrier film has a distinctive foil appearance, and it’s strong and opaque. It is manufactured in a contaminant-free, ISO-certified environment. Order moisture-barrier film online.

Our automotive clean room packaging products are manufactured according to the strictest standards set by the FDA, EU, and ISO:

- 21 CFR177.1520(c), paragraph 2.2 compliant

- European Commission (EU) No 10/2011 compliant as of 4/9/2012.

- Complies with the requirements of Article 4.1 of EU Directive 2011/65/EU (RoHS)

- Complies with California Proposition 65 (The Safe Drinking Water and Toxic Enforcement Act).

We also ensure that our cleanroom packaging does not contain any materials of animal origin or Substances on Very High Concern (SVHC). Substances like natural rubber, natural latex, Fluorotelomers, Perfluorooctanoic acid (PFOA), Perfluorooctane sulfonate (PFC), or Bisphenol are not intentionally added to the product manufacturing process.

Automotive Controlled Environment: Classifications & Requirements

The automotive industry requires ISO-certified cleanrooms with a specific level of cleanliness and contamination control. Cleanrooms built for automotive purposes should meet all the necessary requirements in terms of particle count, air change rate, and ceiling coverage, providing a safe space for automotive research, development, packaging, and assembly.

Automotive Cleanroom Classification

Cleanrooms used in the automotive industry must comply with the ISO Classifications, which refer to cleanroom cleanliness. The ISO Classes range from Class 1, which is the cleanest cleanroom area, to Class 9, defined as the least clean controlled environment. Most automotive cleanrooms require the classification of ISO Class 5-8.

However, ISO requirements may vary depending on the industry-specific aspects and the sensitivity of components produced. For instance, the manufacturing of microchips and electronics will require more stringent ISO standards.

Different ISO standards may apply to the following automotive industry branches:

- Applications involving hydraulic fluid components

- Performance tests of paints and finishes such as CASS

- Quality assurance testing

- Automotive development (production, design, installation, and service).

Automotive Cleanroom Design

Automotive cleanrooms typically feature modular cleanroom design because it is more convenient for working with large automotive parts and equipment. The most common modular cleanroom types used for automotive purposes are HardWall and RigidWall cleanrooms.

Other essential parts of automotive cleanroom design include the following:

- Air filtration system: Your automotive cleanroom should have a proper air filtration system to remove any particles from the air and ensure contaminant-free space. The air filtration system usually consists of prefilters and HEPA filters.

- HVAC: The cleanroom HVAC system controls the temperature, humidity, pressure, and other environmental factors critical in automotive applications.

- Static control: The manufacturing of electric components, sensitive hardware, or sensors requires extreme control of static electricity. The lack of adequate control may increase contamination, put your products at risk of damage, or lead to staff injury.

Automotive Industry Subsectors That Need Cleanroom Packaging

The automotive industry has different subsectors that also need ISO-certified cleanroom and adequate cleanroom packaging for protecting their electronic components safe from contaminants and airborne particles.

The following are the most common automotive subsectors:

- Automotive HVAC market (heating, ventilation, and air conditioning)

- Automotive battery market

- Cockpit electronics market (navigation systems, sensors, passenger controls, etc.)

- Automotive engine oil market.

Pristine Clean Bags®: Next-Level Automotive Clean Room Packaging Supplies

Pristine Clean Bags® is a leader in producing cleanroom packaging supplies for automotive assembly and manufacturing. Our cleanroom bags, tubing, and films are ISO-certified and anti-static, which makes them ideal for different automotive and electronic purposes. We offer premier quality, stellar customer service, on-time delivery, and pricing 20-30% below the US and EU markets.