Medical Device Packaging Supplies

Certified Non-sterile & Sterile Medical Device Plastic Zipper Bags and Tubing

With Pristine Clean Bags®, you won’t have to worry about potential device damages or exposure to contaminants. Our sterile and non-sterile medical device packaging is manufactured in ISO-certified cleanrooms with the highest levels of traceability and conformance. We are constantly improving the quality of our products, adapting them to all medical industry sectors – microbiology, pharmaceuticals, biotechnology, equipment production, and more. Many cleanroom contract medical manufacturers use our tubing and sterile ziplock bags as packaging for medical devices, sampling bags, catheter packaging, needle packaging, therapy packaging, cleanroom kitting, vaccines and many more.

Our custom sterile and non-sterile packaging conveniently stores all medical devices that need to be in a clean condition before they are used. Cleanroom bags, tubing, and polyethylene films are made of virgin, surfactant-free, and non-animal sources that ensure excellent quality and 100% pristine storage for different types of medical tools and equipment.

Why Choose Pristine Packaging for Medical Devices?

Vast Industry Experience

We Cover European & US Markets

Great Pricing & Discounts

ISO-Certified Medical Cleanroom Bags

Compliant with FDA and EU Standards

Custom-Tailored Cleanroom Bags

Packaging for Contract Medical Device Manufacturing Companies

Jarrett Industries is a leading packaging supplier for contract medical device manufacturers. Our line of products feature materials that mitigate the risk of contamination and are manufactured in highly controlled, ISO-certified cleanrooms.

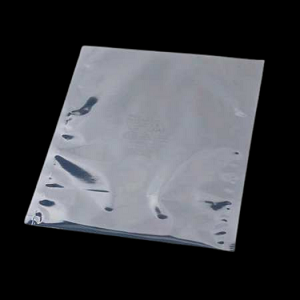

ESD Bags

ESD bags (static shield bags) are perfect for protecting your sensitive electronic devices and semiconductors. If your industry requires safe transport and storage for outside of the safe working area (EPA) look no further than Pristine ESD bags. Protect electronic products like SSD hard drives, motherboards and memory with our ESD shielding bags. Click this link and learn all the technical details about ESD bags.

LDPE Bags

LDPE bags, also known as low-density polyethylene bags, are suitable for general cleanroom applications, including medical uses. These bags are characterized by their incredible strength, moisture barrier, and enhanced clarity. Our LDPE bags are produced in an ISO-certified space, providing unmatched quality. Order LDPE bags online.

HDPE Bags

HDPE, or high-density polyethylene bags, are extremely puncture- and temperature-resistant, have tensile strength, and excellent moisture barrier. As a result, HDPE bags are ideal for storing heavy equipment, remain durable in a wide temperature range, and are perfect for different medical purposes. Order HDPE bags online.

LDPE Easy Tear Bags

LDPE bags with the easy tear formulation are an advanced version of basic LDPE bags. Thanks to tear notches, medical technicians can open the bag quickly and without using sharp blades, scissors, or knives. Easy Tear LDPE bags are available in various thicknesses, with or without re-closeable zippers. Order LDPE Easy Tear bags online.

Cleanroom Poly Tubing

Cleanroom poly tubing is excellent for storing medical equipment that’s longer in length. You can also use it when you’re packing the same item continuously. Order cleanroom poly tubing online.

Nylon/PE Easy Tear Bags

Nylon/PE bags feature extreme puncture and scuff resistance, transparency, and robust design. The easy tear feature allows technicians to open the bag with gloved hands without using sharp tools. Nylon/PE bags are produced in ISO-certified cleanrooms and are convenient for storing sensitive medical devices. Order nylon/PE bags online.

Moisture-Barrier Film

Moisture-barrier film is beneficial for storing sensitive medical equipment that requires the utmost protection from moisture vapor (MVTR) and oxygen transmission (OTR). Moisture-barrier film is extremely strong and opaque and has a distinctive foil appearance. This packaging is manufactured in a pristine, ISO-certified environment. Order moisture-barrier film online.

We want our clients to know that our medical cleanroom packaging complies with the standards regulated by the FDA, EU, and ISO:

- 21 CFR177.1520(c), paragraph 2.2 compliant

- European Commission (EU) No 10/2011 compliant as of 4/9/2012

- Complies with the requirements of Article 4.1 of EU Directive 2011/65/EU (RoHS)

- Complies with California Proposition 65 (The Safe Drinking Water and Toxic Enforcement Act).

Besides, Jarrett Industries makes sure the cleanroom bags do not contain any trace of animal sources or Substances on Very High Concern (SVHC). We do not intentionally add any kind of natural rubber, natural latex, Phthalates, Fluorotelomers, Perfluorooctanoic acid (PFOA), Perfluorooctane sulfonate (PFC), or Bisphenol A to the manufacturing process.

Understanding Medical Equipment Packaging Requirements

Medical cleanrooms are necessary for developing vaccines, pharmacological products and manufacturing essential medical devices. There are three types of medical cleanrooms – medical research cleanrooms, pharmaceutical cleanrooms, and medical device cleanrooms. Each cleanroom will be designed according to the industry’s specific needs and the cleanroom classification requirements.

The Most Common Applications

Packaging bags for medical cleanrooms are necessary for storing critical medical equipment, tools, or substances used for different medical or pharmaceutical purposes. Adequate packaging will keep your medical devices contaminant-free until use, ensuring no bacteria or airborne particles could affect their quality or safety.

Medical packaging bags must meet the following requirements:

- Known and traceable materials

- Non-toxic and odorless substances

- No signs of holes, tears, cracks, or localized thinning

- Designed for medical applications

Consider medical cleanroom packaging for the following purposes:

Medical Research Cleanrooms

Medical research cleanrooms are commonly used for medical experimentation, research, and the development of new treatments. Medical research cleanrooms fall within ISO Class 5-7, meaning that the cleanroom environment must possess an adequate filtration system and allowed particle count.

Medical research cleanrooms are frequently used for the following purposes:

- Research involving blood or stem cells

- Applications working with toxic or infectious substances

- Research and study of infectious diseases, viruses, or cancer

- Vaccine development.

Medical Device Cleanrooms

Medical devices include all the tools used to diagnose, treat, or cure patients. They must be contaminant-free because they come into contact with membranes and tissues, which is why their production and packaging must be conducted in a highly controlled environment.

Most medical devices must be produced, assembled, and packed in cleanrooms compliant with ISO Class 5-8 standards. While non-critical and semi-critical devices fall within the 7-8 ISO Class range, implanted devices and surgical equipment require ISO Class 5 or higher.

Pharmaceutical Cleanrooms

Pharmaceutical cleanrooms are those used for developing and testing chemical treatments for improving health. The choice of a pharmaceutical cleanroom depends on the specific type of substances and procedures used, but pharmaceutical cleanrooms generally comply with ISO 7-5.

As for medical cleanroom design, Hard-wall cleanrooms are the best choice because of their stable and reliable structure. Such structure mitigates the risk of damage and error caused by humidity, temperature, contamination, and similar environmental factors that could affect the product quality or the manufacturing process itself.

Pristine Clean Bags®: Custom Sterile Medical Device Packaging Supplies

Count on Pristine Clean Bags® if your industry depends on pristine conditions and proper packaging choice. Our ISO-certified cleanroom bags are suitable for a wide variety of medical applications, from medical research and development to medical device manufacturing and pharmaceutical uses. All our products comply with the EU and FDA standards and regulations.

Our unique sourcing ability allows us to offer pricing 20-30% off the US and EU markets. With us by your side, you will experience a fusion of superior quality, stellar customer service, and on-time delivery.