Questions To Ask Your Cleanroom Packaging Supplier

July 19, 2021

Why Choose Pristine Clean Bags® as Your Clean Room Packaging Supplier in 2023? (And Beyond)

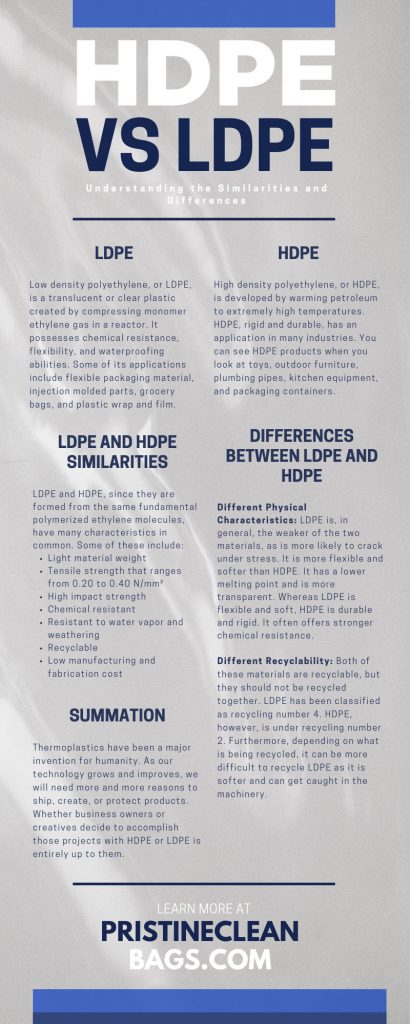

February 7, 2022HDPE vs LDPE: Understanding the Similarities and Differences

Flexible thermoplastic packaging is developed through a process called extrusion, in which plastics are fed through die, or a series of dies. The two most common thermoplastics are low-density polyethylene, or LDPE, and high-density polyethylene, or HDPE.

While HDPE and LDPE maintain many of the same characteristics, they are not entirely the same material. In this article, we will endeavor to help you in understanding the similarities and differences between HDPE and LDPE. This requires that we explore the molecular level of both materials, discuss their applications, and ultimately, from this, derive what is at the heart of the overall advantages and disadvantages of using either of the two materials.

LDPE

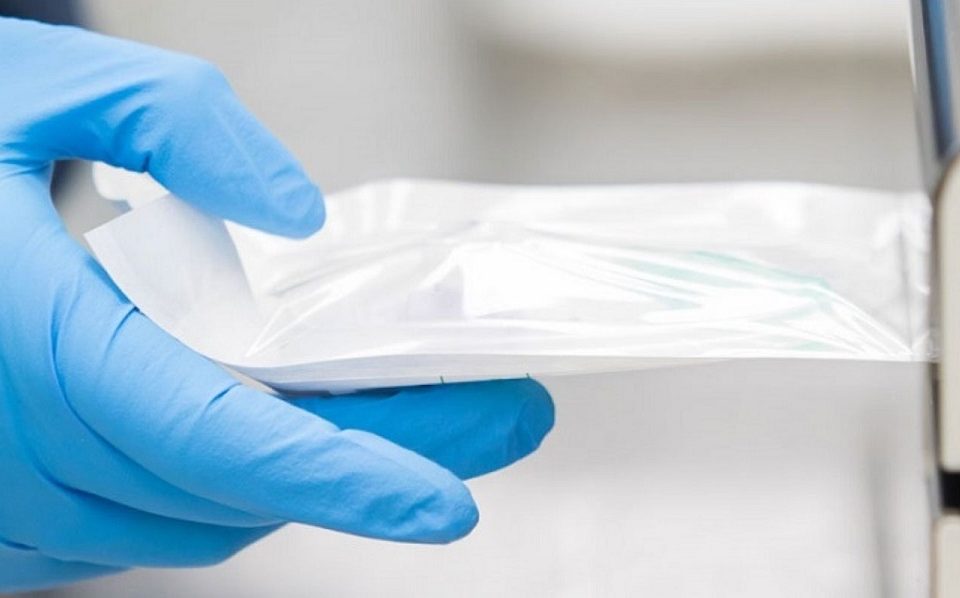

Low density polyethylene, or LDPE, is a translucent or clear plastic that is most often used in the packaging industry, including cleanroom packaging. It possesses chemical resistance, flexibility, and waterproofing abilities.

LDPE is used in the cleanroom industry as a lower cost substrate for safe storage, handling, and shipping of sensitive components that require protection against contamination.

HDPE

High density polyethylene, or HDPE, is more rigid and chemically resistant than LDPE. Because of its durability, it has an application in many industries. It has a higher temperature resistance, higher melting point, and is more resistant to solvents and alcohols.

LDPE and HDPE Similarities

LDPE and HDPE, since they are formed from the same fundamental polymerized ethylene molecules, have many characteristics in common. Some of these include:

- Light material weight

- Tensile strength that ranges from 0.20 to 0.40 N/mm²

- High impact strength

- Chemical resistant

- Resistant to water vapor and weathering

- Recyclability

- Low manufacturing and fabrication cost

Industries That Use Both LDPE and HDPE

Since there are so many applications for LDPE and HDPE, some industries use them both. These industries include:

- Medical Devices

- Packaging

- Life Science

Uses in Medical Devices

Due to its strength and ability to withstand high temperatures, HDPE is frequently used for plastic lab bottles and medical waste containers. Medical and surgical instruments, like catheters and medical tubing, also benefit from HDPE’s resistance to cracking and radiation. LDPE, flexible and tough, is widely utilized as a low-cost yet durable material for many cleanroom applications.

Uses in the Packaging Industry

HDPE, with its easy process and low cost, is often used in the production of plastic packaging. It makes a strong barrier with chemical stability, which means it is excellent for bottles and containers, especially industrial and household chemicals.

LDPD is typically used for packaging when heat sealing is necessary, like in film. LDPE poly bags have great strength, work as moisture barriers, and are translucent.

Uses in Life Science

Since both LDPE and HDPE are nontoxic, maintain a high degree of break resistance, and non-contaminating (when extruded using only virgin resins, and without surfactants), they are frequently used to protect life science and medical products. HDPE is used for products that require more impact strength protection, chemical resistance, and heat resistance.

Differences Between LDPE and HDPE

Understanding the similarities and differences between HDPE and LDPE is a process that starts with uncovering the differences in their composition. LDPE and HDPE have intrinsically disparate compositions, which create differences in their physical characteristics and recyclability. The polymer chains that create both materials are branched into LDPE, while, in HDPE, the polymers have a crystalline structure. This distinction is at the heart of the different characteristics in each material.

Different Physical Characteristics

LDPE is, in general, the weaker of the two materials, as it is more likely to stretch under stress. It is more flexible and softer than HDPE. It has a lower melting point and is more transparent.

Whereas LDPE is flexible and soft, HDPE is durable and rigid. It offers stronger chemical resistance. It can hold under higher temperatures than LDPE, and its crystalline structure results in better strength and opacity.

Different Recyclability

Both of these materials are recyclable, but they should not be recycled together. LDPE has been classified as recycling number 4. HDPE, however, is under recycling number 2. Furthermore, depending on what is being recycled, it can be more difficult to recycle LDPE as it is softer and can get caught in the machinery.

Advantages and Disadvantages of LDPE

The advantages of LDPE primarily boil down to its wide variety of uses at a low cost. LDPE is:

- Resistant to chemicals

- Easily processed and molded

- Water resistant

- Can be processed as transparent

Its disadvantages, however, have everything to do with its weak makeup and lack of durability. LDPE is:

- Prone to stretch when under stress

- Cannot handle extremely high or low temperatures

- Has almost no UV resistance

Advantages and Disadvantage of HDPE

HDPE comes with its fair share of advantages and disadvantages. Some of its better qualities are:

- A great variety of applications

- Its low temperature impact resistance

- Its tensile strength

- Its chemical resistance

- It is water resistant

Although it is the stronger of the two, it would be wrong to assume that it does not come with its own disadvantages. Some of these include :

- Could crack from stress

- Highly flammable

- Cannot be composted

Summation

Thermoplastics have been a major invention for humanity. As our technology grows and improves, we will need more and more reasons to ship, create, or protect products. Whether businessowners or creatives decide to accomplish those projects with HDPE or LDPE is entirely up to them. But they can rest easy knowing that both options are available. Hopefully, this article gave you an idea of the advantages, disadvantages, applications, and differences of low-density polyethylene and high-density polyethylene.

HDPE vs LDPE: Infographic

Pristine Cleanroom Bags are manufactured according to the highest quality standards in the environmental control packaging industry. We provide the following cleanroom materials: shrink film, barrier bags, high and low-density polyethylene, nylon, tear notches, easy-open, zip lock, printed, sheeting, anti-static, FEP. Pristine Cleanroom Bags also has custom cleanroom resin blends. Our cleanroom packaging items are supported by an ISO-certified quality system and continuous environmental monitoring.

Our global supply chain enables us to support our customer’s facilities within the US and Europe. In addition, our unique strategic sourcing ability allows us to offer cleanroom bags and films at prices that are 20-30% below the US and EU markets. Call customer support at (410) 581-0303 – our experts will be happy to answer any questions about tubing, films and bags for cleanrooms.