HDPE vs LDPE: Understanding the Similarities and Differences

August 2, 2021

Understanding Sustainability in Flex Packaging

June 2, 2023Why Choose Pristine Clean Bags® as Your Clean Room Packaging Supplier in 2023? (And Beyond)

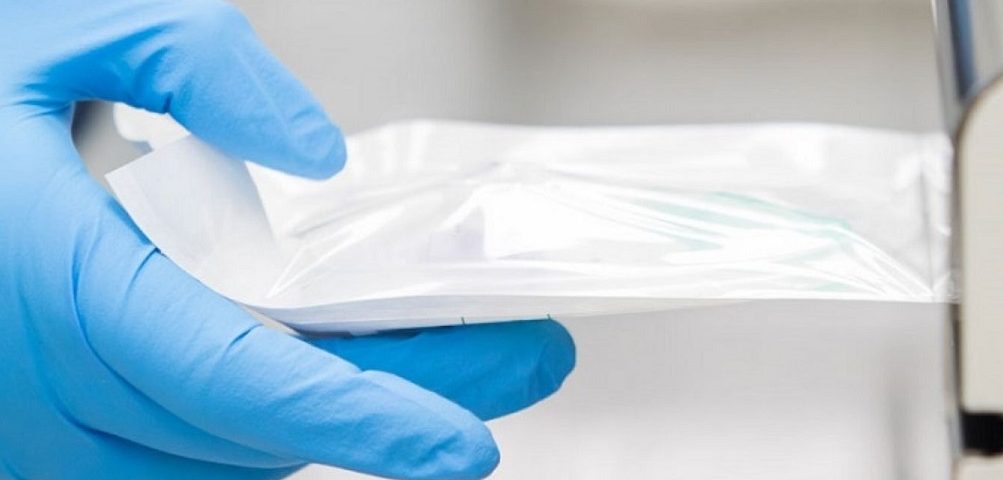

Industries whose products have been in high demand lately, including aerospace, electronics, pharmaceutical, medical device manufacturing, and automotive, require a certain level of cleanliness to ensure the items they produce remain intact. It increased the need for high-quality cleanroom packaging to preserve the product’s optimal function even when it leaves a controlled environment.

The process of building cleanrooms and providing certain cleanliness levels is a huge investment. Unfortunately, many companies went out of business due to the lack of adequate cleanroom consumables, including cleanroom packaging. The role of cleanroom bags and tubing is quintessential, and its importance shouldn’t be overlooked – that way, you’ll be able to highlight the benefits of your products and prove your company’s credibility.

If you’re looking for cleanroom packaging supplies and don’t know from where to start, you’ve come to the right place. We have gathered the most frequently asked questions regarding cleanroom packaging to help you make a smart decision and choose Pristine Clean Bags® as a cleanroom bag supplier.

Let’s dive into it!

Do You Offer Cleanroom Nylon Bags?

Do You Have Cleanroom Bags in Stock?

Does My Industry Need Cleanroom Packaging?

Do You Offer Bags with Customized Dimension?

Are Your Cleanroom Packaging Supplies ISO-Certified?

Are Your Cleanroom Bags Made of FDA-Approved Materials?

How Does Your Supply Chain Look Like?

What is Cleanliness?

The term “cleanliness” is pretty relative as it depends on the industry and the nature of the product manufactured. Some industries require higher cleanliness levels than others, and their cleanroom needs go a step further.

It’s vital to understand that particles are the cleanroom’s biggest enemy. Therefore, a controlled environment uses different HVAC devices, like HEPA or ULPA filters to filter out pollutants like aerosol particles, airborne particles, and dust. Cleanrooms are classified into different degrees of contamination, depending on the number of particles allowed in the area per cubic meter. Factors like temperature, humidity, and airflow are also controlled inside a cleanroom.

Do You Offer Cleanroom Poly Bags?

Yes. We offer a broad range of cleanroom poly bags for different industries requiring the use of high-quality cleanroom consumables for storing their sensitive components. Cleanroom poly bags offered by Pristine Clean Bags® meet the needs of any industry. They are versatile and made of dependable virgin resins, which makes them the number one choice among businesses whose products are susceptible to pollutants.

Our polyethylene bags are produced in an ISO-certified environment, and they are convenient for ISO Class 5, 6, and 7 areas. You can rest assured that our poly bags are made of virgin resins and never reused materials that reduce the risk of contamination. In addition, our cleanroom supplies comply with FDA and EU regulations.

Do You Have LDPE Poly Bags?

Pristine Clean Bags® delivers top-quality LDPE bags suitable for general cleanroom uses. LDPE refers to a low-density polyethylene, and it’s characterized by excellent strength, moisture retention capabilities, and great transparency. LDPE bags are clear and reliable but don’t have the best temperature resistance. For that reason, it’s not recommended to use them for freezer or microwave applications.

LDPE cleanroom bags are commonly used in the aerospace, automotive, electronic, chemical, and pharmaceutical industries, but other sectors can benefit from them, as well.

Do You Offer ZIP Poly Bags?

Here comes another yes. Pristine Clean Bags® aims to deliver the most convenient cleanroom packaging for your specific needs, including LDPE Easy Tear Bags. The easy tear formulation ensures that technicians can open the bag without scissors or knives, preventing potential injuries or damages to the product.

Easy Tear LDPE bags are available in various thicknesses, with or without re-closeable zippers. Since they feature low-density polyethylene, they shouldn’t be used in extreme temperatures. However, they are pretty suitable for gamma-irradiated products.

Do You Offer HDPE Poly Bags?

HDPE (high-density polyethylene) bags are the best choice for purposes that require exceptional puncture resistance, tensile strength, and moisture retention properties. HDPE bags are often translucent and incredibly strong, and unlike LDPE, high-density polyethylene can withstand extreme temperatures.

They are commonly used in the food manufacturing industry, medical and pharmaceutical purposes, life sciences, and other applications seeking strong and temperature-resistant packaging to safeguard their items from external factors. However, HDPE is not the best option for items that require clear and transparent packaging.

Do You Provide Cleanroom Poly Tubing?

Another cleanroom bag type available in our store is cleanroom poly tubing. Cleanroom poly tubing is convenient for packaging items lengthwise, but it has other benefits that make your daily processes much more straightforward. For example, cleanroom tubing opens at its mouth, ensuring the product is fully encapsulated and safe for shipment.

Cleanroom tubing is pretty versatile, and various industries use it for different applications. It allows you to cut the piece from the rest of the roll, heat seal it, and staple it the way it fits your needs. Another great benefit of cleanroom poly tubing reflects in its durability, strength, and ease of use.

Are Your Cleanroom Bags Anti-Static?

Industries that manufacture sensitive electronic components, microchips, circuit boards, and other parts susceptible to damage due to electrostatic discharge (ESD) need special anti-static or static shielding bags to safeguard their products.

We offer cleanroom bags coated with a special anti-static agent to mitigate the risk of triboelectric charge buildup resulting from the interference with hair and fabric. However, anti-static bags aren’t suitable for shipping or transporting ESD-sensitive items. On the other hand, static shielding bags offer a safe transit of sensitive products, and we’ll be happy to deliver them to you at any time!

Do You Have Moisture-Barrier Films?

If you’re looking for cleanroom packaging with enhanced moisture retention properties, we have something for you – high-quality moisture-barrier films. Moisture-barrier films for cleanroom purposes offer exceptional vapor protection and oxygen transmission. The film features a blend of nylon, foil, and polyethylene, which provides a strong and opaque appearance.

The moisture-barrier film doesn’t contain any static dissipative coating, which minimizes outgassing and non-volatile residue. You can rest assured that the moisture-barrier film provided by Pristine is manufactured in an ISO-certified clean room and is safe for use inside a controlled environment.

Do You Offer Cleanroom Nylon Bags?

You can rely on Pristine Clean Bags® to deliver high-quality nylon bags for your specific cleanroom purposes. Nylon bags feature a laminated structure composed of low-density polyethylene and a biaxially oriented nylon layer. In addition, they are strong, transparent, puncture-, and scuff-resistant, which makes them suitable for various cleanroom purposes.

Industries commonly use nylon/PE bags to reduce tears and scuffing due to friction rubbing. Besides, they’re suitable for vacuum applications and applications requiring moisture retention. Pristine ensures that the entire series of nylon/PE bags are manufactured in an ISO-certified area and are safe for standard cleanroom uses.

Do You Have Cleanroom Bags in Stock?

Yes, we have cleanroom bags you can order from our official website as we speak. If our available products don’t meet your needs, don’t hesitate to contact our sales rep and tell us more about your goals and expectations. We can craft custom-tailored solutions for your specific industry’s applications and cleanroom’s ISO classification.

Does My Industry Need Cleanroom Packaging?

Industries whose products can be severely affected by contaminants and airborne particles must provide a cleanroom area for the product manufacturing process. If you’re in some of the following industries, you’ll need a cleanroom for your daily business operations:

Manufacturing Industry

The manufacturing industry keeps pace with the latest technologies, so it needs cleanrooms for its regular operations. Cleanroom packaging supplies for the manufacturing industry are made of virgin and surfactant-free materials and are suitable for the industry’s subsectors:

- Electronic part manufacturing

- Biotechnology

- Life sciences

- Food manufacturing

- Automotive parts manufacturing

Medical & Pharmaceutical Industries

Industries dedicated to medical device manufacturing and drug production must ensure their products are safe for consumers. Therefore, they utilize the best cleanroom bags for storing sensitive tools, drugs, vaccines, cosmetics, and equipment susceptible to contamination.

Cleanroom bags for medical and pharmaceutical purposes feature virgin materials free from any harmful substance. They ensure the maximum level of traceability and conformance, and owners can choose among different types of bags depending on their unique needs – LDPE, HDPE, cleanroom poly tubing, nylon bags, or exceptional moisture-barrier films.

The following subsectors benefit from the cleanroom bags:

- Biotechnology

- Medical technology

- Drug delivery

- Foods and nutraceuticals

- Companies selling companies to other companies

- Drug research/production for gene therapy, immunotherapy, cell therapy, vaccines, etc.

Electronic Industry

The electronic industry deals with contaminants and electrostatic discharge on a daily basis. Both factors can cause severe damage to electronic components and sensitive parts, affecting their functionality and overall quality.

All subsectors of the electronic industry must use appropriate cleanrooms and anti-static/static shielding packaging supplies to maintain the functionality of circuit boards, microchips, and other device components widely used today. For example:

- Semiconductor supply and manufacturing services

- Industrial equipment manufacturing

- Networking and communication equipment

- Computer and office equipment

- Consumer electronics and home appliances

- Optical device manufacturing

Defense and Aerospace Industry

The defense and aerospace industry is another field that requires strict use of cleanrooms and cleanroom packaging supplies for conducting daily business operations. High-quality cleanroom packaging supplies play a vital role in the defense industry, particularly because they’re suitable for storing sensitive components of rockets, gliders, drones, space crafts, and other inventions.

The following defense and aerospace industry subsectors must manufacture their products inside a controlled environment and use proper clean room supplies to prevent potential damages.

- Spacecraft and satellite component manufacturing

- Engine component manufacturing

- Microchip and sensor production

- Companies that launch rockets and spacecraft (Boeing and SpaceX)

- Airport infrastructure and aviation security

Automotive Industry

Modern vehicles feature essential electronic components and circuit boards that must work optimally to deliver exceptional performance and long-lasting quality. One of the prerequisites for producing high-quality and reliable automotive parts lies in using cleanrooms and cleanroom supplies that limit the contamination levels inside a controlled environment.

Depending on their specific needs and requirements, the automotive industry and its subsectors may benefit from LDPE, HDPE, nylon, poly tubing, moisture-barrier films, or another customized cleanroom packaging.

The following automotive industry subsectors should use proper cleanroom packaging supplies for their daily operations and purposes:

- Automotive HVAC market

- Automotive battery market

- Cockpit electronics market (navigation systems, sensors, etc.)

- Automotive engine oil market

Do You Offer Bags with Customized Dimension?

Yes, we do. We understand that not all solutions work for everyone, and each customer has different goals and needs. For that reason, we give you the opportunity to choose the exact bag dimensions you need for storing your products, ensuring you get cleanroom-made, ISO-certified, and FDA-approved solutions in line with your industry’s requirements.

Are Your Cleanroom Packaging Supplies ISO-Certified?

Pristine cleanroom bags are produced in an ISO Class 5 environment and come with full traceability and documentation. Our supplies carry ISO 14001:2015 certifications and maintain the highest level of conformance to meet your specific needs.

Are Your Cleanroom Bags Made of FDA-Approved Materials?

Our cleanroom bags and tubing are made from virgin, surfactant-free, never reused, and non-animal origin materials that ensure the optimum level of cleanliness inside a controlled environment. If you’re working in the food manufacturing industry or similar sectors where it’s necessary to follow the FDA regulations, rest assured that our cleanroom bags and tubing won’t let you down.

How Does Your Supply Chain Look Like?

Businesses have become fast-paced, and we try to keep track of the most innovative global trends by offering a more flexible supply chain management. We support multiple locations across Europe and the US, ensuring our VMI, JIT, or consignment smoothly integrates into your supply chain.

How Much are Your Cleanroom Bags?

Our competitive advantage lies in our ability to offer pricing 20-30% below the US and European markets. Don’t hesitate to reach out to our customer support today and start saving huge on premier cleanroom packaging supplies for your industry.

How Long I Wait for Delivery?

If you choose cleanroom bags we have on stock, we guarantee reliable and on-time delivery. If you’re looking for customized options, we’ll set a shipping deadline depending on your specific requirements regarding the product.

Pristine Clean Bags®: #1 Cleanroom Packaging Supplier You Can Trust

Pristine Clean Bags® is a trustworthy cleanroom packaging supplier you can count on whenever you need custom-tailored, high-quality cleanroom bags, poly tubing, moisture-barrier films, and similar consumables for your industry’s specific needs. Besides, our ISO-certified and FDA-approved materials ensure optimal cleanliness levels and the utmost protection from external factors that could damage the items inside.

Please reach out to us to discuss your options and find the best cleanroom packaging solution for your specific needs and industry requirements.